PU Flooring

Indoor sports hall PU flooring is indispensable for sports halls with their flexible and shock absorbing properties consisting of 3 layers. While providing comfortable sports and activity opportunities with their shock absorbing and smooth surface, they also ensure the safety of the athlete.

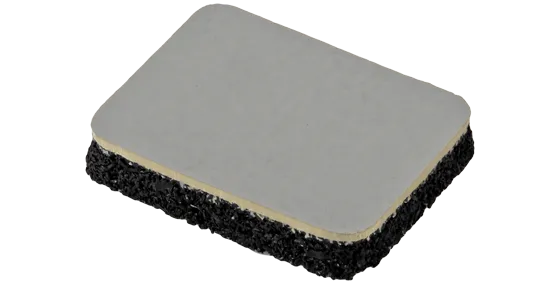

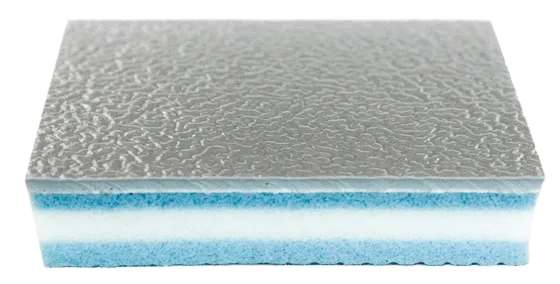

PU Flooring consists of 4 layers with a thickness of 10–13 mm. Approved by the international FIBA, PU Flooring is a product with high abrasion resistance.

- Can be constructed between 10–13 mm.

- Consists of 4 layers.

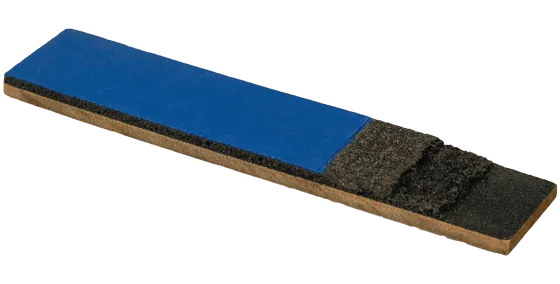

- SBR shockpad + PU sealer + self-leveling PU + top coat PU.

- Complies with FIBA standards.

- Provides a comfortable and hygienic surface structure.

- Ensures safe game performance with its shock absorption.

- High abrasion resistance.

- Antibacterial and easy to clean.

- Suitable for very hot and very cold climates.

- Waterproof.

- Low maintenance costs.

- Preferred in indoor sports halls.

Projects

Frequently Asked Questions

1. How to make a polyurethane indoor sports hall?

It is applied with a roller to increase the adhesion of synthetic production to the ground. Then, the SBR layer is mixed with 20% binder to increase shock absorbency and applied with a finisher machine. In order to close the pores of the SBR shockpad layer, elastic PU is pulled with a nailless trowel. Self-leveling PU is applied evenly to the ground with a nailed trowel and the final coat of paint is applied in 1 or 2 layers.

2. How much do gym polyurethane flooring prices cost?

Prices are variable as it is applied as 8mm - 10mm - 12mm. Price is calculated according to the meterage and thickness information.

3. What are the advantages of sports hall polyurethane flooring?

While providing comfortable sports and activity opportunities with its shock absorbing and smooth surface, it also ensures the safety of the athlete.

4. How long does the indoor sports halls PU coating last?

In general, it is an average of 7 days depending on the size of the project.

5. How much do polyurethane-based sports flooring costs?

Prices are variable as it is applied as 8mm - 10mm - 12mm. Price is calculated according to the meterage and thickness information.

Sports Flooring

Other Products